THE tradition of making models of Barney’s Market Cross began as a challenge and now the former apprentice who created it is considering making one for himself.

Many readers have been in touch since the Teesdale Mercury ran a story about the silver-plated model of the Market Cross. Thanks to information they provided, we now know that models of the Market Cross were created by apprentices in the engineering department of Glaxo during the 1960s and 1970s. One of the silver-plated models was presented as a leaving gift for the then chief executive John Musgrave in 1991.

Barnard Castle resident Roy Jones, who worked in the machine shop at GSK, said he and his fellow workers made more than one Market Cross in a variety of metals.

He added: “We made quite a few of them. It all started when the chief engineer came from Ulverston. To prove we were better than the Ulverston factory, he challenged us to make a model of the locomotive that was outside the factory there.”

Mr Jones helped create the miniature railway engine but can’t remember if they won the challenge. He added: “There was a lot of work involved polishing the metal, not just the welding. I remember Keith Minikin made the hooks for the front and back of the loco. The chief never said anything about the model, but that’s where making the models started from.”

Under the watchful eye of engineer Dennis Luckhurst, he said apprentices were tasked with making a number of intricate models. As well as the locomotive and Market Cross they fabricated a variety of gifts, including a chess set and even a toilet pan for the director.

Memories were also stirred for former engineering apprentice John Dowson, of Barnard Castle.

He said: “I didn’t see the original story as I was away on holiday, but when I got back, I saw the letters about it.”

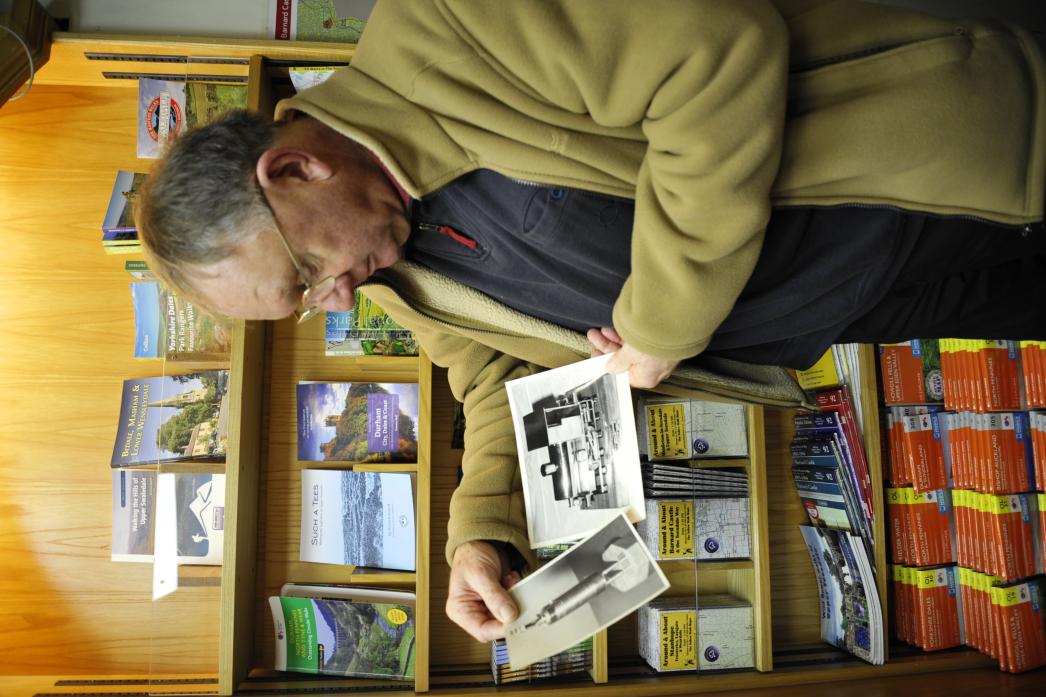

Mr Dowson, who joined the factory team in 1978 and retired six years ago, added: “I made two of them. We made them from about 1981 to 1982. The first one I made would have been for the chief engineer.

“My biggest regret is that I never put my mark on them. They were made in brass and one of the apprentices, Alan Bell, started making one in stainless steel but it distorted too much.

“I remember it took a long time to make them, probably about six months. Roy Jones was our mentor in the machine shop and all parts of the model were made there, but it was sent out to be plated.

“When I retired, I did have some thoughts about making one for myself as I have the plans, but I never did. I may do so now if I can dig out the plans.”